Water Savings EXPERTS

A full-service water treatment company specializing in U.S. government tested and validated water saving technologies for cooling towers and other process water systems.

U.S. GOVERNMENT TESTING AND VALIDATIONS

U.S. Dept of Energy Better Buildings (Wastewater): Cleveland Cliffs Case Study 2024

U.S. Dept of Energy Better Buildings Challenge: LABBC Case Study 2022

Juliette Gordon Low Federal Courthouse GPG: Study 044 January 2020

Los Angeles City Hall Technical Report: NREL/TP-5500-73911 August 2019

GSA Report on Dynamic Water Technologies Water Treatment: NREL/ Savannah, GA December 2018

This baby food plant is part of a Global nutrition company. Located in Arkansas, it utilizes two (2) Marley Quadraflow towers and was operating at 2½ cycles with traditional chemical treatment. The site was experiencing biologic contamination and bio growth in the process water, requiring regular shutdowns for manual cleaning. In May of 2022, DWT installed one DSR16 unit on the CT400 compressor towers. Since the DSR system was implemented, the water quality has drastically improved allowing for significant increases in cycles. In the past 5 months the system has required zero blowdown. The overall biologic count has consistently been well within industry standards.

News Flash!

SAVING WATER AND ELIMINATING CHEMICALS

The use of cooling towers for manufacturing processes and comfort cooling for large buildings presents three well known challenges in the safe and efficient management of process water treatment. Scale, corrosion, and bio-contamination are the cause of major problems with commercial and industrial process water systems. Inefficient heat transfer, plugging, and outright failure are all too common. Treatment of all three must be achieved to maintain effective water treatment.

WHY TRADITIONAL TREATMENT FAILS

Chemical treatment does not have an answer for changes in makeup water composition or for changes in heat demand.

Many chemical treatments go awry, oscillating between scale forming and corrosion while blooming dangerous amounts of bio-contamination.

Most chemical treatment programs require running low cycles which wastes millions of gallons of water.

Chemical treatment does not have an answer for Silica. Typically, chemical treatment programs will not operate successfully above 150 ppm silica. Electrochemical solutions can handle silica within site-specific limitations.

WHY ELECTROCHEMICAL TECHNOLOGY SUCCEEDS

Dynamic Water Technologies (DWT) has developed a patented technology that utilizes controlled electrolysis to manage scaling, corrosion, and bio-contamination instead of using hazardous chemicals. The system speeds the natural process of scaling within the controlled environment of reactor chambers where the scale is sequestered for later removal.

The advanced PLC control system continuously monitors changing water conditions and adjusts the process accordingly.

SoCal Gas, Pico Rivera, Ca) Dynamic Water offers their DSR systems pre-plumbed and pre-wired on custom unitary skids. The skid incorporates reactor units, controls, and pump. The pre-packaged system dramatically reduces on-site installation labor.

US Government Test Result Summaries

NATIONAL RENEWABLE ENERGY LABORATORY (NREL)

NREL is a national laboratory of the U.S. Department of Energy Office of Energy Efficiency & Renewable Energy.

The U.S. Department of Energy’s High Impact Technology Catalyst program (HIT) Catalyst is designed to help identify, prioritize, and deploy cost-effective, innovative, energy-efficient technology solutions, enabling federal and commercial building owners and operators to make sound investment decisions in next generation technologies based on real-world performance testing.

NREL TEST CONDUCTED AT LOS ANGELES CITY HALL

The DWT technology was deployed on a cooling tower in a large Los Angeles City Hall office building in Los Angeles, California. The baseline performance and DWT system performances were monitored during the 2018 cooling season. A multivariable-linear regression model was developed to estimate annual water savings for 2018. The DWT system saved an estimated 20% or 1.16 million.

The system also removed historical scale from the condenser tubes and cooling tower media.

NREL Conclusions: The DWT system eliminated the need for the use of the scale and corrosion inhibiting chemicals. A small amount of chlorine was added during the first few months of operation as a precautionary measure and was phased out when it was proven that safe conditions were maintained. Removal of calcium and other scale-producing minerals by the DWT system reduced the need for blowdown, which led to an estimated annual water savings of 1.16 million gallons, or 20% of the makeup water. The biological growth and potential for corrosion were also safely maintained by the DWT system through the automated control system.

Result: LA City Hall wins 2020 Innovation Award for Better Buildings

City Hall East achieves 20% water Savings and 85% Reduction in Sewer Charges Through Electrochemical Water Treatment System earning them the prestigious LA Better Buildings Challenge (LABBC) award.

See more about the U.S. Dept of Energy Better Buildings Challenge here

THE UNITED STATES GENERAL SERVICES ADMINISTRATION (GSA)

The (GSA) is an agency of the United States Government managing and supporting the basic functioning of federal agencies. GSA develops government-wide cost-minimizing policies and other management tasks. They also are tasked with leading the way in green building design, construction, retrofit and sustainable operations and maintenance.

GSA test conducted for the Juliette Gordon Low Federal Building, Savannah GA

Juliette Gordon Low Federal Courthouse Report 038

Testing and Evaluation of a Chemical- Free Cooling Tower Water Treatment Technology

Case Studies

Los Angeles City Hall Case Study

NASA Case Study

Gilead, Oceanside Case Study

TECHNOLOGY

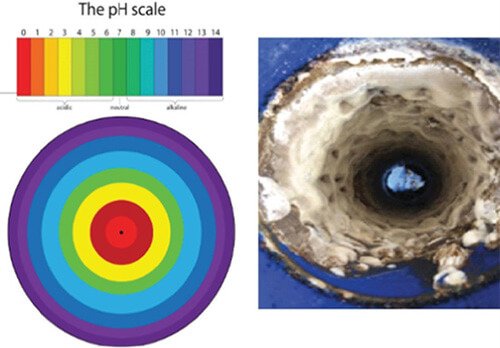

SCALE CONTROL

Scaling in the system can cause blockages to the water flow and reduces system efficiency.

The DSR process creates a controlled, partial electrolysis in the water. This process precipitates unstable, scale forming minerals inside the reactors instead of on heat transfer surfaces in the tower, chiller, and process piping. It will also progressively remove existing scale.

The DWT system consists of a reactor skid, small pump, and controller installed as a side stream to continually treat a portion of the cooling tower water flow. The system uses electrolysis of the water in tubular reactors to create a favorable environment for precipitation of the concentrated minerals within the confines of the tubes. The electrolysis also creates conditions that kill biological growth while maintaining a dynamic balance of relatively high pH and Ca+ ion concentrations to minimize the potential for corrosion.

CORROSION CONTROL

Corrosion is irreversible and has the highest cost if left untreated. In addition to reducing the life of equipment, corroded surface areas become zones for scale deposition and biomass growth.

The electrolysis process generates a pH gradient within the reactor providing an alkaline, non-corrosive pH at the perimeter of the reactor which allows for the process water to average between 8.2 – 9.0pH, well within a non-corrosive range.

BIOCONTAMINATION CONTROL

The electrochemical process continuously generates hypochlorous acid and chlorine without adding any chemicals.

The biocide level is adjustable and disinfects the process water, killing algae, viruses, and bacteria, including the pathogenic legionella. Control of biologics protects against biofilm issues.

The electrochemical water treatment has consistently shown to outperform chemical treatment in the control of biologics.

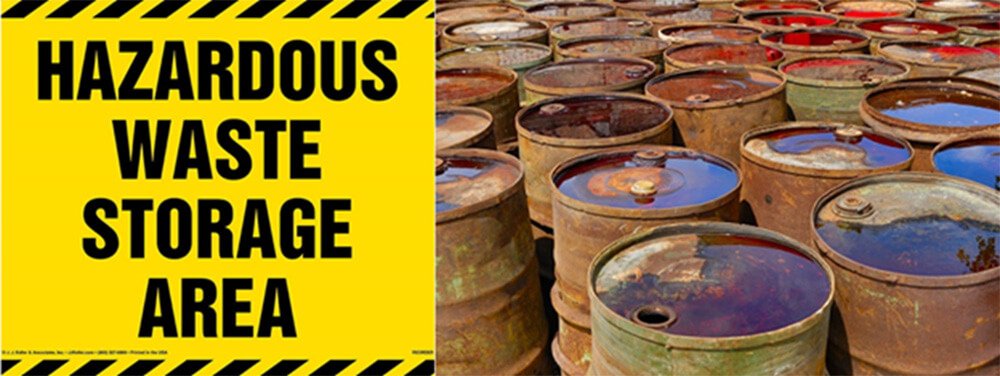

ELIMINATION OF HAZARDOUS CHEMICALS

Electrochemical solutions provide for treatment without the need for chemicals. Most of the chemicals typically used in process water treatment are hazardous or toxic and can pose serious risk for spills and injury. Even small spills require immediate attention to mitigate.

Established in 1928, this baby food products company is part of an international nutrition group offering over 300 food products for babies, toddlers, and infants. The company operates in over 50 countries. The company operates in more than 50 countries. This plant, located in Ft Smith AK, utilizes two (2) Marley Quadraflow towers and was operating at 2½ cycles with traditional chemical treatment. The site was experiencing biological contamination and bio growth in the process water, requiring regular shutdowns for manual cleaning. In May of 2022, DWT installed a DSR16 unit on the CT400 compressor towers. Since the DSR system was implemented, the water quality has drastically improved allowing for significant increases in cycles. In the past 5 months, the system has required zero blowdown. The overall biologic count has consistently been well within industry standards.

AT&T Building, Van Nuys, CA

AT&T, Van Nuys, CA: DSR16M Unit

SoCal Gas, Anaheim, CA: DSR8 Unit

Designated by the U.S. Environmental Protection Agency as an “Energy Star®” Building, the SoCalGas® Energy Resource Center is a model of advanced, energy-efficient, and environmentally sensitive building technology: (1) DSR8M Unit

SoCal Gas, Redlands, CA: DSR4M

SoCal Gas Building H, Pico Rivera, CA: (2) DSR8MP Units

SoCal Gas, Downey, CA: DSR8MP Unit

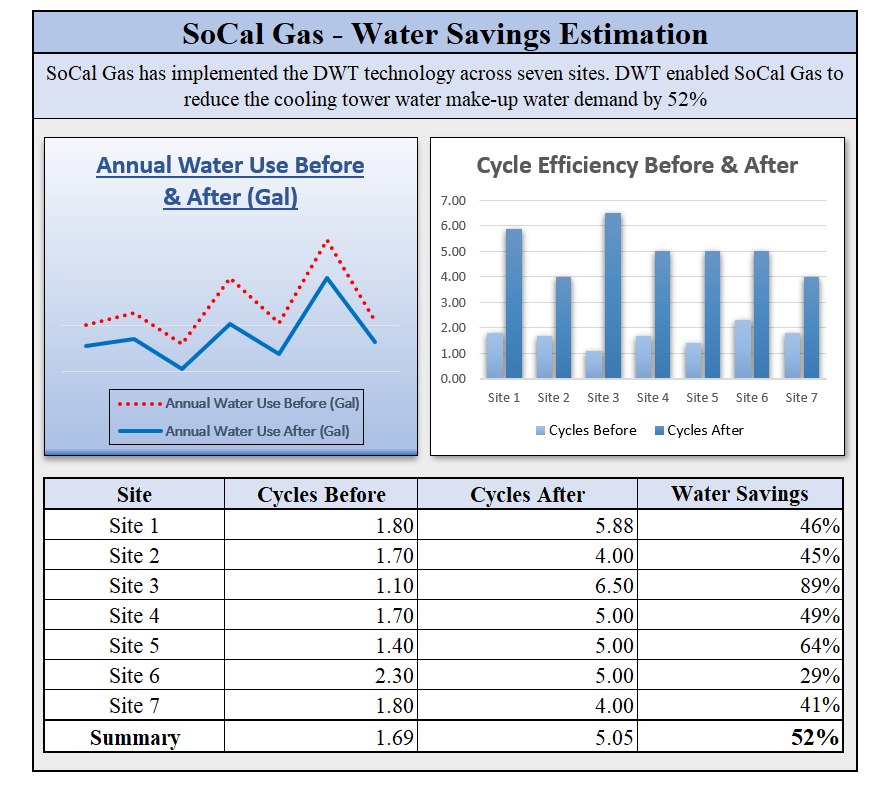

Summary of Water Savings at SoCal Gas Locations; SoCalGas sought to implement technology to provide water savings and improved system performance in their cooling towers and chillers. They installed an electrochemical treatment system from DWT at the Energy Resource Center in early 2018. SoCalGas reported a water savings at this location of over 50%. Based on the performance of the system at the ERC facility, SoCalGas has installed systems in five additional locations.

JV Farms Mobile Cooling Equipment is used to cool produce as it is picked to increase shelf-life. It is equipped with cooling towers and DSR8MP Unit, truck mounted, increasing efficiency, and saving water. JV Farms Mobile Cooling Equipment: DSR8MP Unit

Los Angeles Department of Water and Power: (3) DSR16M Units

Juliette Gordon Low Federal Courthouse – Savannah, GA: US General Services Administration facility selected for validation testing under the High Impact Technology program. Project oversight was managed by the US Department of Energy – National Renewable Energy Laboratory. Courthouse Cooling Tower

Los Angeles City Hall and City Hall East Buildings- The DWT electrochemical system implemented by the City of Los Angeles in 2018. It was monitored by NREL / DOE to validate the overall performance and savings. The findings showed 20% reduction in water use, 85% sewer discharge reduction and 100% elimination of chemicals.

This installation is for a national aeronautics government group which specializes in aerospace development. This site is on a military installation located in California, whose challenges included water scarcity, bio-contamination, and scale issues. They turned to Dynamic Water for a sustainable solution to their water treatment.

Gilead Sciences: (2) DSR16MP

Kinder Morgan – Topock, AZ: Kinder Morgan, Inc. is one of the largest energy infrastructure companies in North America. The company owns an interest in or operates approximately 85,000 miles of pipelines and 152 terminals. The Topock station was experiencing excessive scale on its evaporative condenser towers prior to switching from traditional chemical treatment.

Kaiser, Modesto, CA: The electrochemical DSR system was engineered to accommodate the existing 3,000-ton cooling tower and chiller. The equipment design called for eight DWT DSR8 Units and four 660 GPM centrifugal pumps. The system supply is connected to the equalization line and returns treated water to each basin.

Kinder Morgan, Topock, AZ: DWT designed a solution utilizing two DSR8 reactor skids to provide water treatment and eliminate the need for scale inhibitors, corrosion inhibitors, acids, and biocides.

Kaiser, Modesto, CA: (8) DSR8 Units

Smith’s-Kroger 311, Las Vegas, NV: DSR12MP Unit

Americold Building A, Henderson, NV: (3) DSR8

Kaiser, Modesto, CA: Layout Drawings

DSR20M Assembly Drawing

Pinal Energy, located in Maricopa, AZ, is the first ethanol production facility in Arizona. Beginning production in 2008, the plan provides a local source of ethanol available at a rate of 50 million gallons from roughly 18 million bushels of grain acquired from local producers and from the Midwest. As a zero liquid discharge facility, everything at the site is recycled. The CO2 is even captured and recycled for soft drink, dry ice, and hydroponics. The DWT was installed in February of 2018.

Roche VLF, Roche Tissue Diagnostics, Marana, AZ

Roche Molecular Systems, Pleasanton, CA